Secure networking of real-time and alarm data

DataHub middleware from Skkynet was used by ABB to support highly redundant, secure networking of OPC A&E and real-time data on the Trans-Anatolian Natural Gas Pipeline (TANAP) project in Turkey.

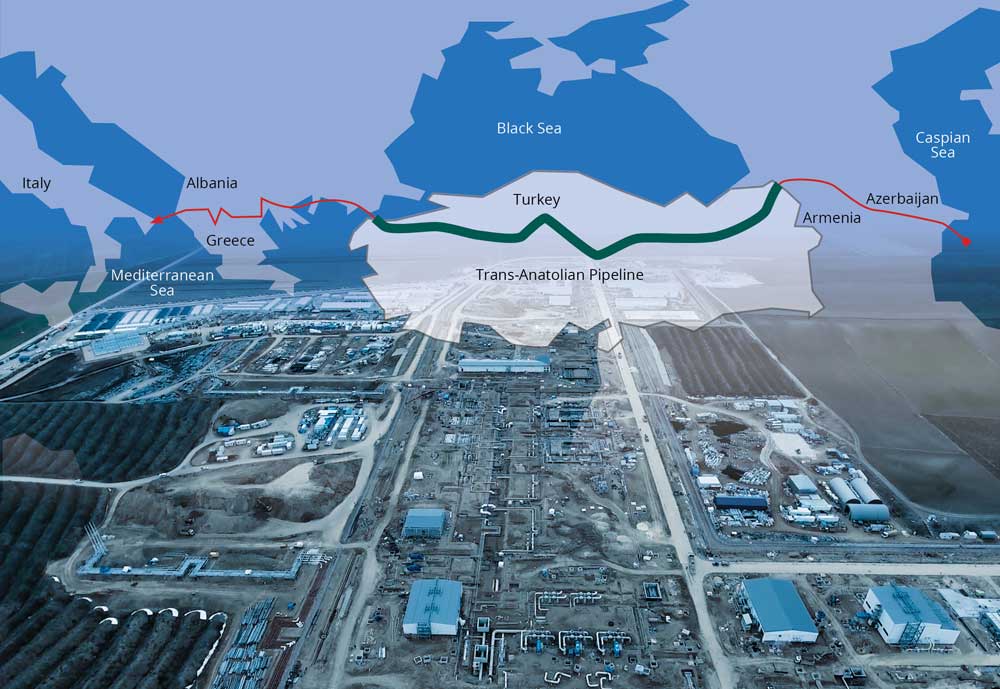

The recently-completed pipeline extends 1850 kilometers across the country of Turkey, making up a significant part of the Southern Gas Corridor that is responsible for supplying more than five percent of Europe’s natural gas. The telecommunications, security and control infrastructure for the TANAP pipeline was implemented by ABB’s Process Automation Division, and uses the DataHub middleware to support highly redundant, secure communications of real-time and alarm data.

“TANAP is an important and prestigious project, not just for Turkey, but internationally,” said Yakup Yilmaz, Operations Technical Support Group Manager, TANAP. “It is critical both for Turkey and Europe’s energy security. The cooperation between TANAP and ABB and its various vendors has helped make the project run smoothly, and achieve the success we have attained.” Scaling mountains, crossing pasturelands, and running under the sea, the pipeline is the longest and largest-diameter pipeline in Turkey, the Middle East, and Europe. Initially it will carry 16 billion cubic feet of gas per year, with the potential of over 30 billion in the future. Four Metering Stations and two Compressor Stations connected to a Main Control Centre ensure that the gas is transported safely and efficiently.

Reliable data communication is critical to the secure operation of the pipeline. Every aspect of operation from equipment functioning to leak detection is monitored, controlled, stored, and transmitted between the remote stations and the control centre. Hundreds of thousands of OPC DA and OPC A&E data values are tunnelled by the DataHub across redundant, state-of-the-art fibre optic networks with VSAT satellite backup, and are seamlessly integrated with SCADA systems for monitoring and supervisory control.

“Almost every functionality that the DataHub offers gets used here,” said Sam Harrasi, PCS Engineer for ABB, the project technical leader. “Some of the features of the DataHub that we have used are unique to the DataHub, features that other companies with similar products aren’t able to even offer.”

The DataHub’s architecture and approach to OPC tunnelling is well suited to this project. Because it isolates the OPC connection from the networked tunnel connection, the DataHub can just as easily transmit OPC A&E alarm data across the tunnel as OPC DA real-time data. And since it supports OPC server-to-server bridging, it can connect OPC servers at the control centre with OPC servers in the field. Perhaps most important, the DataHub’s built-in redundancy support has allowed the ABB team to configure a highly reliable system with multiple layers of redundancy.

In addition to the DataHub’s standard integration features, the ABB team also took advantage of its built-in Scripting module to create a customized monitoring solution. “We are effectively using the script capability to monitor the health of the DataHub and connected software across the entire pipeline, not only of our own systems, but of other suppliers as well,” said Harrasi. “Code in each of the DataHubs on the ABB side sends out a continuous heartbeat, and listens to the heartbeat of all the servers—ABB and others. And we’ve created a diagnosis web page that allows us to see all of the DataHubs at once across the entire pipeline.”

Needless to say, on such a large system there were integration challenges. “This project is really pushing the boundaries of what the DataHub can do,” Harrasi said. “This is the first time we are using it at this scale. We ran into some unexpected problems, and I couldn’t speak more highly of the support that the Skkynet team has given. I’ve never seen any supplier be more supportive.”

The mission of TANAP is to “build and operate a secure and reliable gas transmission pipeline system with the highest quality while adhering to high health & safety and social & environmental standards.” TANAP and ABB have designed and implemented a very secure and reliable control system for what is being called an “engineering masterpiece.” We at Skkynet are proud to be a part of it.