Manufacturers and Machine Builders Weigh In on IIoT

With all the conversation swirling around about Industry 4.0 and the Industrial IoT, you sometimes have to wonder what’s actually trickling down to those people who are expected to buy in, like manufacturers and machine builders. The bottom line is that someone is going to have to invest in the IIoT, and they expect to get a return on that investment. IIoT proponents are counting on manufacturing companies and OEMs to put some skin in the game. But who is talking to them?

At least one person is. Larry Asher, Director of Operations at Bachelor Controls Inc., a certified member of the Control System Integrators Association (CSIA), has been meeting with long-term customers in a number of industrial fields, and asking them for their thoughts on the IIoT. Their responses indicate an overall positive view of the potential.

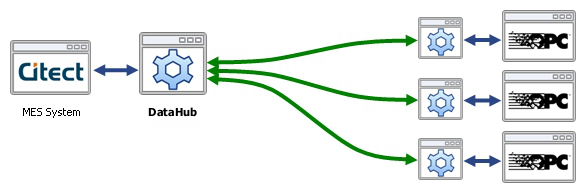

Asher first reiterates a growing understanding that the IIoT is not just a new term for industrial networking, or SCADA as usual. He says, “Though it is true that networking has existed as part of industrial control solutions for many years, traditional isolated control networks will not support the level of integration required for large-scale data and analytics, nor will they support the number of connected devices that will be a part of IIoT-based solutions. IIoT-based solutions demand connectivity, accessibility and security, making the network infrastructure critical.”

He then shares the insights garnered from his conversations, organized into four areas that the IIoT is expected to impact: data analysis, mobile/remote access, supply chain integration, and preventative maintenance.

Summary of Insights

Here is a summary of how the manufacturers and machine builders he met with view the impact of the IIoT:

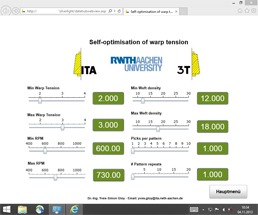

Data and Analytics: Everyone agrees that investing in IIoT to enhance data collection and develop more sophisticated and powerful analytics is a good thing. Applying this higher level of analysis is already impacting procedures and control implementation on the plant floor. Some manufacturers are even revising company organizational structures to bring in people who can maximize performance and profit using IIoT data.

Mobile/Remote Access: Access to data via mobile devices and/or from remote locations has seen less interest, but that is expected to change. Right now the implementation is fairly low, despite the significant number of products and options available, perhaps due to a perception of high cost. But, as Asher reports, “mobility remains as a central theme and poised for rapid growth with a change in the value proposition.”

Supply Chain Integration: As to supply chain integration, there was a wide range of experience. Some saw little or no difference between current practices and what the IIoT has to offer, while others reported that the integration is so complete that suppliers now effectively have direct access to user inventory levels.

Preventative Maintenance: Manufacturers and OEMs alike appreciate the value of IIoT-based preventative maintenance. With machines and equipment connected directly to the vendor, manufacturers can automatically generate maintenance work orders or request spare parts. Vendors gain a competitive advantage when they are able to monitor and remotely service their equipment 24/7, which also provides them with a source of recurring revenue.

Overall, the views of those at manufacturing plants responsible for ensuring ROI validate the practicality and cost-effectiveness of the Industrial IoT. As word gets out, and more decision-makers understand the benefits, we expect to see increased levels of adoption.