Eyebrows were raised among the industrial automation community last week when the well-known Kaspersky Labs issued a report titled OPC UA Security Analysis that lists 17 security issues in the OPC UA protocol and products. While we see no reason to doubt their methodology, we take a different approach to the question.

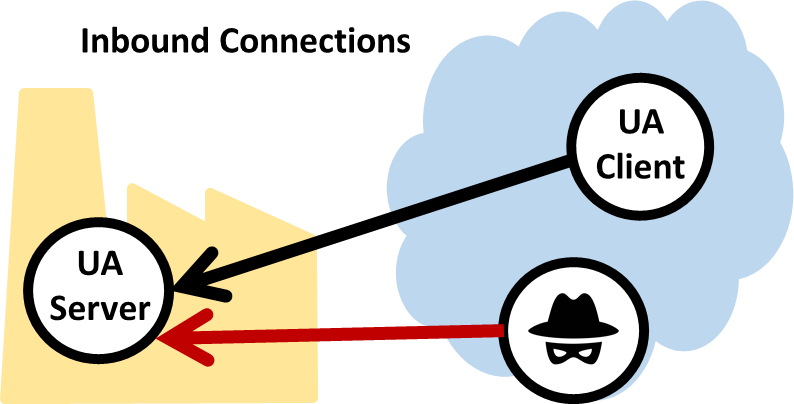

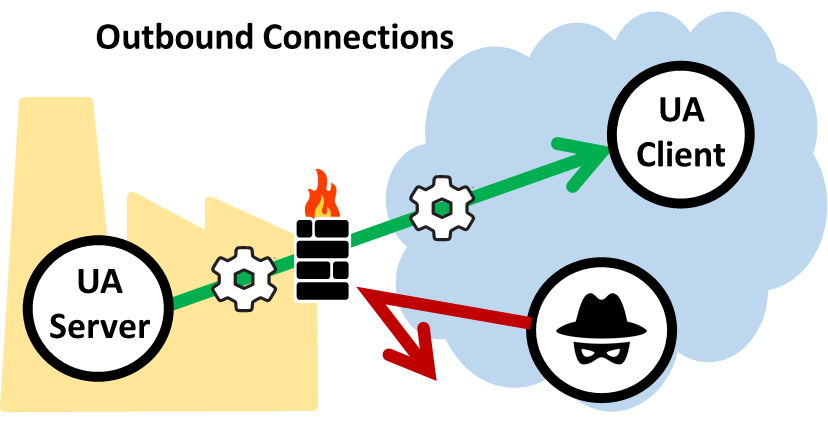

As we see it, the real issue is not the OPC UA protocol itself. OPC UA was created to allow client/server networking for industrial communication. The flaws that Kaspersky identified were visible on an OPC UA server that, by definition, is listening for network connections from OPC UA clients. Any application that listens for connections on a network can equally be a point of attack for a malicious hacker. This is not unique to OPC UA—it is a fact of the design of TCP/IP networks. Period.

Think about it. How did Kaspersky Labs discover the vulnerabilities in OPC UA and related products? Using a technique called “fuzzing”, they used a specially-constructed client application to send a rapid-fire barrage of messages at the UA server, each of which was slightly altered, or “mutated”, in some way from a standard message. Sooner or later one of these messages would crash the server or uncover an exploitable vulnerability. This technique can be used on any network-connected server, like a web server, VPN server, RDP server or vendor-supplied remote access server.

We would argue that Kaspersky Labs was searching for symptoms while overlooking the cause. What the report does not address, and indeed it is so obvious that it is easily overlooked, is that this kind of attack can only succeed if the intruder has access to the server in the first place. All software has bugs. Any program exposed to the Internet is fair game. However, as long as your servers are running on a trusted network and you keep all inbound firewall ports closed, you don’t run the risk of an attack from outside, no matter how persistent or devious the attacker may be.