Skkynet Joins Canadian Business Mission to Japan

This past month Skkynet’s President, Paul Thomas, teamed up with a group of Ontario business leaders for a business mission to Japan. Led by Ontario Premier Kathleen Wynne and the Ontario Trade Commission, the mission met with companies like NTT-Data, Rakuten, and Softbank, and succeeded in signing 15 trade agreements valued at more than $120 million.

A high point of the visit was a signing ceremony for a memo of understanding between Cogent and BellChild at the Canadian Embassy in Tokyo to launch the next generation of the iBRESS Service in 2017. “We are pleased to strengthen our relationship with BellChild in this way,” said Thomas, “and build on the success of the current iBRESS Secure Micro Cloud Service, which we have been offering jointly for the past 18 months. Adding the capabilities of the SkkyHub™ service to BellChild’s portfolio will significantly enhance their ability to serve their customers.”

Shown in the picture, left to right:

- Mr. Ian Burney, Ambassador of Canada to Japan

- Mr. Paul Thomas, President of Skkynet

- Mr. Yoshikuni Fujita, President of BellChild

- Ms. Kathleen Wynne, Premier of Ontario

- Mr. Minoru Yamazaki, Senior Advisor, Cogent DataHub Application Centre (Japan)

The signing ceremony was one of many events and meetings held over a period of two weeks to establish stronger bonds of collaboration between Skkynet’s Canadian and Japanese subisidaries (Cogent and NiC), and their Japanese partners and affiliated companies. Building on ten years of personal, business, and technical relationships, this visit not only rekindled old friendships, but also opened new doors. Here are some highlights:

Site visits to the Tokyo Institute of Technology, as well as the Nagoya Institute of Technology, where a team of professors has been testing the new OPC UA features of the Cogent DataHub for internal communications over OPC UA in a simultated plant environment.

The launch of the Alliance Partner Group (APG), leading proponents of the Industrial IoT that share Skkynet’s and BellChild’s vision, including TOA, IBS Japan, Kobata Gauge, Japan-Direx, Device Drivers, Haneron, MACNICA Techstar Co., and Puerto, as well as Skkynet, Cogent, NiC, and BellChild.

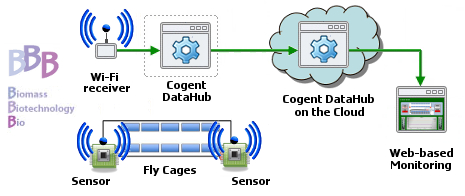

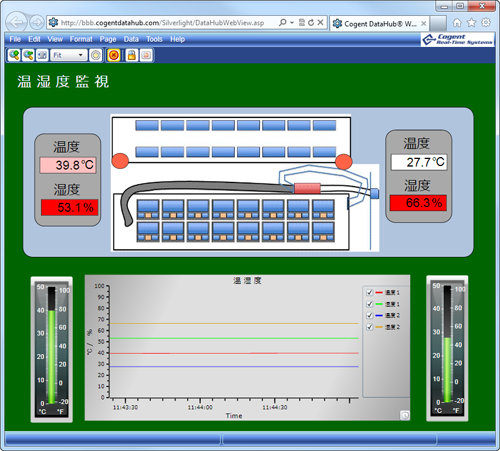

Meetings with the ThunderCloud Alliance as a group, as well as with individual members. The ThunderCloud Alliance is a nine company alliance to provide Industrie 4.0 and Industrial IoT hardware, software, and services to the world market. Each company is contributes from its own specialized field. TOA Musendenki Co., Ltd is in charge of communication and various sensor devices. BellChild Co., Ltd is responsible for cloud servers. Kobata Gauge Manufacturing provides various sensors. Haneron Corporation offers remote monitoring equipment. NiC is responsible for industrial networks. Nissin Systems Co., Ltd. is in charge of control systems and embedded software. Puerto Co., Ltd develops industrial protocols, and provides expertise in OPC UA. Japan Direx Corporation does real-time network intelligence analysis. Cogent Real-Time Systems provides real-time data connectivity middleware to communicate between devices (M2M) and remote monitoring.

Leading up to these events, Skkynet/BellChild iBRESS Service was used to power demos at the following trade shows:

- ET2016 (demos by Nissin, Renesas, Renesas Easton, and BellChild)

- JIMTOF 2016 (demos by MACNICA and BellChild)

- Monozukuri Business Fair 2016, Osaka (demos by BellChild)

“The business mission was a resounding success, and personally very satisfying,” said Thomas. “We have sown a lot of seeds, and look forward to seeing how they grow in the coming year.”