ExxonMobil Seeks Open Automation Solutions

At the most recent ARC Industry Forum in Orlando, ExxonMobil announced that they are not satisfied with business as usual when it comes to industrial automation, and they are looking for something far superior to what is currently being offered. On January 14, 2016, ExxonMobil announced that they had awarded a contract to Lockheed Martin to serve as the systems integrator in the early stage development of a next-generation open and secure automation system for process industries. Lockheed Martin is tasked to seek out the architecture and tools needed for an “open, standards-based, secure and interoperable control system” that can be seamlessly integrated with existing facilities, as well as new and future systems. ExxonMobil wants the hardware and software components to be commercially available and able to function in all current DCS markets.

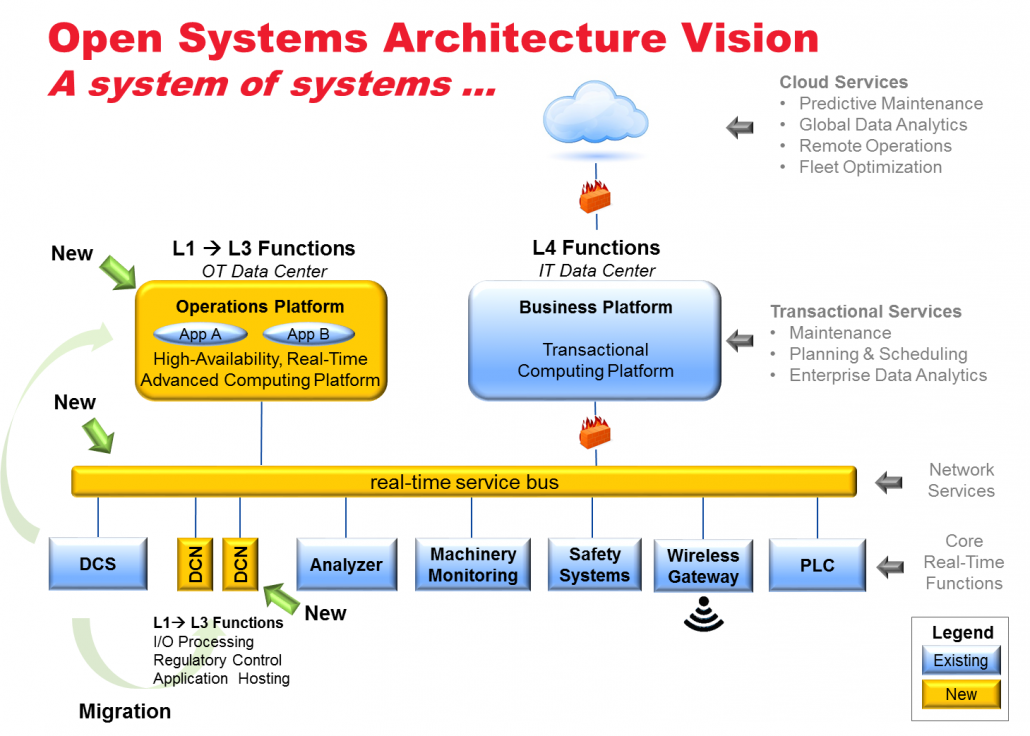

Rather than simply replace their aging systems with the current state of the art, which is expensive, inflexible, and closed, ExxonMobil wants to leverage new, open, IoT, wireless, and cloud technologies to cut costs, enhance security, and reduce development time. As with other, adjacent areas of technology, they want to see a step-change improvements, not incremental or bolted-on changes to obsolete architectures.

Originally presented at Industry Day on January 26, 2016

Their vision for open automation is standards-based, secure, and interoperable, which will:

- Promote innovation & value creation

- Effortlessly integrate best-in-class components

- Afford access to leading-edge capability & performance

- Preserve the asset owner’s application software

- Significantly lower the cost of future replacement

- Employ an adaptive intrinsic security model

This vision reads like a list of Skkynet connectivity solutions features and benefits:

- SkkyHub, DataHub, and the ETK foster innovation and value creation by providing open-standards, real-time data connectivity for hardware and software from almost any vendor.

- These Skkynet tools allow users to integrate data from virtually any components.

- This kind of real-time data integration enables each component in turn to perform at its highest capacity.

- Any generation of equipment, from legacy to state-of-the-art, can be integrated.

- Connecting modules can be replaced, and the system itself gets continually updated.

- Connections from the DataHub or ETK to SkkyHub are secure by design.

We are currently in communication with Lockheed Martin, and bringing these advantages to ExxonMobil’s attention. We share their vision, and offer tested, verified, working solutions.